Product Details

Products Description

This filter is designed for filtration of liquids with solid particles and colloidal materials.

It adopts suction nozzle cleaning method with two-stage filtration to ensure the complete cleaning of the screen with minimum water consumption and without stopping the filtration process.

The filtration ratings can be 25~800um, and the flow rate up to 1500M3/H.

1. Fully automatic back washing, continuous flow during back washing;

2. 2 stages filtration, high filtration precision, large amount of treated water;

3. Suitable for a lot of water qualities, such as tap water, surface water, circulatingcooling water, etc.;

4. Compact structure, simple installation and easy maintenance;

5. Multi-layer sintered mesh has good filtering effect, high strength and long life.

1. Industry: Plastic&textile, Food&beverage, Chemical, steel industry, Power generation, Petrochemical, Mining, Electronics, Pharmaceutical, Pulp&paper, Automotive

2. Agricultural irrigation.

3. Sea water: Desalination

4. Municipal: Water supply, Drinking water, Waste water.

Product Details

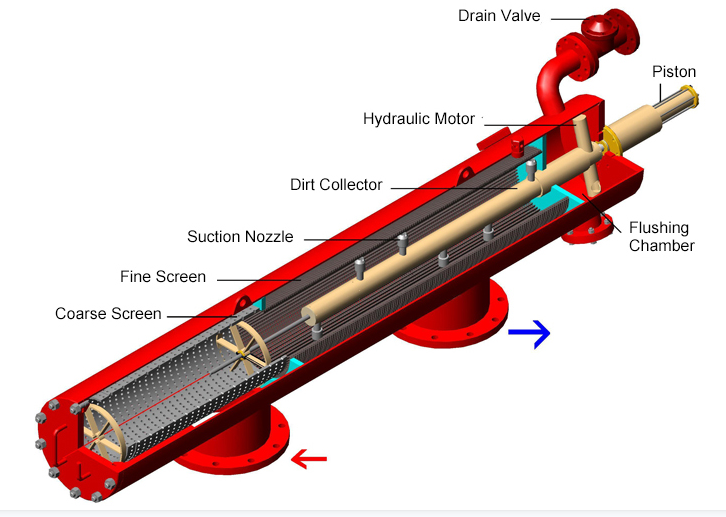

Dirty water flows in to the filter through the inlet across the filtering element. The

Solid particles and impurities will be stuck by the filtering element and the clean water will exit from the output.

When pre-set time is reached, or the pre-set differential pressure is reached, the brain of the filter(electric control box) will instruct the filter to start cleaning.

During the flushing cycle, the flushing valve opens, pressure is released from the hydraulic piston and waste water is discharged through the flushing valve. Pressure in the hydraulic motor chamber and the dirt collector is significantly lowered causing the dirt collector nozzles move along and rotate cleaning the whole internal screen surface. The flushing cycle takes 12-18 seconds.

The flushing valve closes at the end of the cycle, pressure reapplied to the piston, moving the nozzles back to their rest position, and the filter is cleaned.

The inlet/outlet connections of the filters are by flanges

This filter is equipped with an electric control box(Not PLC but simple control box to save cost, also can do true PLC if requested), and is supplied ready to work with valves, pressure gauges, differential pressure switch etc.

The horizontal configuration is equipped with coarse screen to stop big particles, its function is to protect the moving parts and the filter cartridge. The coarse screen can be made of SS304, or SS316L.

Recommend Products

Company Profile

Zhengzhou Fluidguard Machinery Equipment Corp.

Zhengzhou Fluidguard is a leading manufacturer of various filtration and purification products and equipment. Having been in this industry for more than 15 years, our product line has been greatly expanded.

Now our main products include: hydraulic filters, compressor filters, water treatment equipment and oil purifiers. In ourcompany,we always adhere to the principle of "Quality First" to provide the best service to customers around the world.

Over the years, our products have been sold to more than 50 countries in the world, and have won the trust of all customers with the best quality and best service.

But we know this is not the end. Every day is a new beginning!

We put more energy into work, consider more for customers, and are committed to providing better products and service to all customers in the future, We are always ready to serve new customers. Our greatest joy is to bring our best quality products to more customers, so that more customers can enjoy our best quality products and warm service.

Package and Shipping

FAQ

1. What products do you have?

Our products are mainly include 4 series:

Hydraulic filters used from many industries such as coal industry, power plant, steel meel etc.

Air compressor parts(Air oil separator, oil filter, air filter, line filter, cooler etc)

Water treatment equipments

Oil filtration equipments.

2. Are you a manufacturer or a trading company?

We are a manufacturer with good reputation in China as well as many other countries.

3. The filters you provide are original or replacement?

The filters we provide are not original, but good replacement for the big brands in the Hydraulic and Air Compressor industries.

4. How is your quality and price?

We know the market competition is fierce, so we are trying our best to lower the cost; but at the same time, quality is always the

first priority in our company.

We will never sacrifice quality for any reason, this is our bottom line.

5. What's your lead Time?

Around 7-10 days for most filter elements

Around 15 days for water treatment equipments and small oil filter cart

Around 25-30 days for the Oil Coalescer purifier and Vacuum oil purifier

Zhengzhou Fluidguard Machinery Equipment Co., Ltd. TEL: 0086-0373-5128206

Zhengzhou Fluidguard is a collection of filter strainer, filter element, oil purifier and air compressor design and manufacturing, online sales and marketing as one of the modern manufacturers