Product Details

Products Description

The filter uses quartz sand as the filter medium. Under a certain pressure, the water with higher turbidity is filtered through a certain thickness of granular or non-granular quartz sand, effectively intercepting and removing suspended solids, organic matter, and Colloid particles, microorganisms, chlorine, smell and some heavy metal ions, etc., ultimately achieve the effect of reducing water turbidity and purifying water quality.

1. Mainly used for water treatment to remove turbidity, softened water, electrodialysis, and reverse osmosis pre-treatment, and can also be used for surface water and groundwater. Can effectively remove suspended solids, organic matter, colloids, silt, etc.in water.

2. It can be widely used in electronic power, petrochemical industry, metallurgy and electroplating, paper and textile, pharmaceutical dialysis, food and beverage, drinking water, water for factories and enterprises, swimming pools, etc. It can meet the needs of liquid filtration in various industries.

Product Details

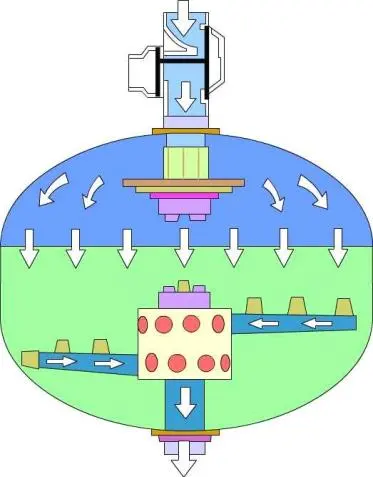

Filtration mode

When the system is in the filtration mode, the feeding water passes through the upper water distributor, cooperates with the spherical shell, and reaches the packing layer in the filter in a nearly advection state. When water flows through the packing layer, impurities are trapped in the packing layer. The collector at the bottom of the filter collects and flows the filtered water evenly Out. Advection filtration determines that the filter can still achieve a good filtration effect at a high flow rate.

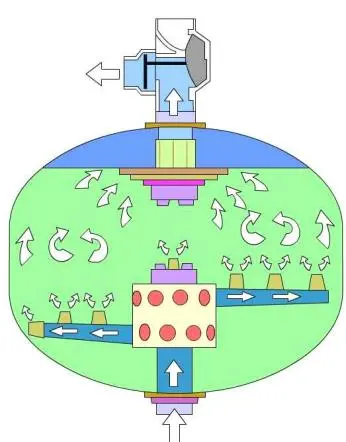

Back washing mode

As impurities accumulate in the packing layer, the head loss (i.e, pressure difference) will continue to increase. When the pressure difference reaches a certain set limit or the filtration time reaches the set value, the system will automatically switch to the back washing mode to clean the packing layer and remove accumulated impurities. For the system, regular back washing to remove the accumulated impurities are necessary.

When the system enters the back washing mode, the on-off position of the three-way valve is changed through PLC control (the inlet is closed and the sewage outlet is open), and the filtered water in the other filter tanks flows into the filter tank to do the back washing work. Because of system pressure, during back washing, the packing layer of the filter unit is washed up under the impact of the water flow, and the impurities are discharged through the drain port of the three-way valve.

In the system, the specially designed water collector makes the packing layer form an internal circulation during the back washing mode, and the packing are scrubbed with each other to maximize the backwash efficiency, reduce the required back washing water, and no sand run out. When the back washing ends, the valve returns to the filtration

mode, and the next filter unit enters the back washing mode. Generally, a system consists of multiple filter tanks (units), which are doing back washing in sequence to ensure continuous flow during back washing.

Recommend Products

Company Profile

Zhengzhou Fluidguard Machinery Equipment Corp.

Zhengzhou Fluid guard is a leading manufacturer of various filtration and purification products and equipment. Having been in this industry for more than 15 years, our product line has been greatly expanded.

Now our main products include: hydraulic filters, compressor filters, water treatment equipment and oil purifiers.

In our company, we always adhere to the principle of "Quality First" to provide the best service to customers around the world.

Over the years, our products have been sold to more than 50 countries in the world, and have won the trust of all customers with the best quality and best service.

But we know this is not the end. Every day is a new beginning!

We put more energy into work, consider more for customers, and are committed to providing better products and services to all customers in the future,

We are always ready to serve new customers. Our greatest joy is to bring our best quality products to more customers, so that more customers can enjoy our best quality products and warm service.

Application

Package and Shipping

FAQ

1.What products do you have?

Our products are mainly including 4 series:

Hydraulic filters used from many industries such as coal industry, power plant, steel mill etc.

Air compressor parts( Air oil separator, oil filter, air filter, line filter, cooler etc. )

Water treatment equipments

Oil filtration equipments.

2.Are you a manufacturer or a trading company?

We are a manufacturer with good reputation in China as well as many other countries.

3.The filters you provide are original or replacement?

The filters we provide are not original, but good replacement for the big brands in the Hydraulic and Air Compressor industries.

4.How is your quality and price?

We know the market competition is fierce, so we are trying our best to lower the cost; but at the same time, quality is always the

First priority in our company.

We will never sacrifice quality for any reason, this is our bottom line.

5.What's your lead Time?

Around 7-10 days for most filter elements

Around 15 days for water treatment equipments and small oil filter cart

Around 25-30 days for the Oil Coalescer purifier and Vacuum oil purifier

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Zhengzhou Fluidguard Machinery Equipment Co., Ltd. TEL: 0086-0373-5128206

Zhengzhou Fluidguard is a collection of filter strainer, filter element, oil purifier and air compressor design and manufacturing, online sales and marketing as one of the modern manufacturers