Application:Waste Oil Refinery Equipment

Function:Remove Water

Raw material:Carbon Steel /Stainless steel

Get QuotationProduct Details

Products Description

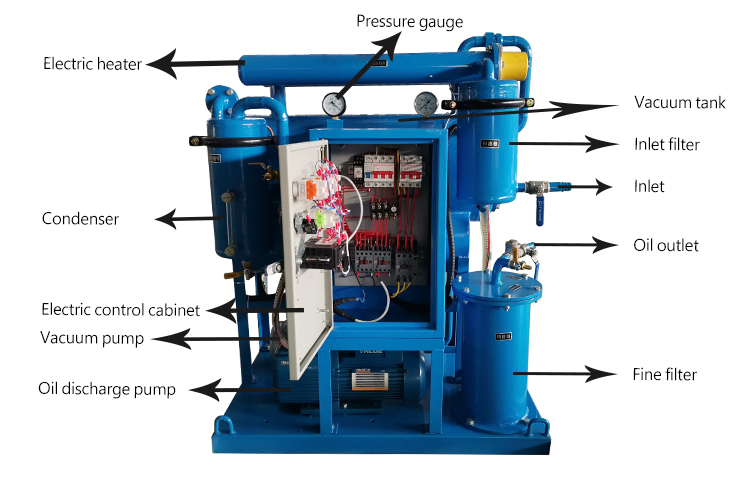

Vacuum oil purifier

This machine is mainly used to deal with unqualified transformer oil, turbine oil, hydraulic oil, mechanical oil, switch oil, etc.

It can remove the gas, moisture and mechanical impurities in the oil, so that the oil is qualified for application.

The machine has the characteristics of small size, high efficiency, and convenient movement, which is especially suitable for on-site operations, and can dry the moisture of the electric equipment, and it can also conveniently carry

out the vacuum oiling of the electric equipment.

This machine adopts oil-water separation technology that combines thin film vacuum evaporation and spray drying. It sets the vacuum pumping rate and heating power to match the flow rate. It is equipped with high-efficiency degassing elements, so that the machine has the best degassing and dehydration function.

This machine is specially designed with an oil level controller, an oil level observation window, and an oil return adjustment system to facilitate the observation of the oil level and ease the vacuum release as required.

Product Details

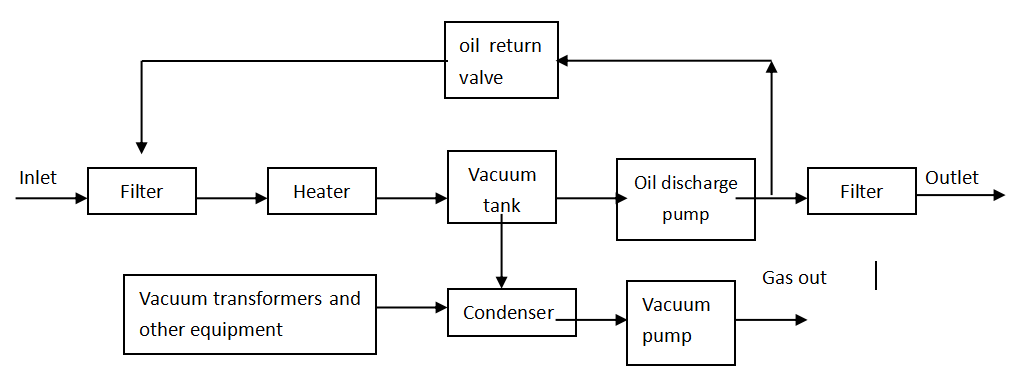

Work Flow

When the oil purifier is working, the oil to be treated is filtered by the coarse filter and heated by the heater, and then enters the vacuum tank. The oil and water are separated in the vacuum tank, and the separated water vapor is condensed into water or pumped out by the vacuum pump; the oil without water and vapor is pumped out by the oil discharge pump, and then discharged through the outlet filter.

Recommend Products

Company Profile

Zhengzhou Fluidguard Machinery Equipment Corp.

Zhengzhou Fluidguard is a leading manufacturer of various filtration and purification products and equipment. Having been in this industry for more than 15 years, our product line has been greatly expanded.

Now our main products include: hydraulic filters, compressor filters, water treatment equipment and oil purifiers. In

our company,we always adhere to the principle of "Quality First" to provide the best service to customers around the world.

Over the years, our products have been sold to more than 50 countries in the world, and have won the trust of all customers with the best quality and best service.

But we know this is not the end. Every day is a new beginning!

We put more energy into work, consider more for customers, and are committed to providing better products and service to all customers in the future, We are always ready to serve new customers. Our greatest joy is to bring our best quality products to more customers, so that more customers can enjoy our best quality products and warm service.

Buyer Feedback

Application

Package and Shipping

FAQ

1. What products do you have?

Our products are mainly include 4 series:

Hydraulic filters used from many industries such as coal industry, power plant, steel meel etc.

Air compressor parts(Air oil separator, oil filter, air filter, line filter, cooler etc)

Water treatment equipments

Oil filtration equipments.

2. Are you a manufacturer or a trading company?

We are a manufacturer with good reputation in China as well as many other countries.

3. The filters you provide are original or replacement?

The filters we provide are not original, but good replacement for the big brands in the Hydraulic and Air Compressor industries.

4. How is your quality and price?

We know the market competition is fierce, so we are trying our best to lower the cost; but at the same time, quality is always the

first priority in our company.

We will never sacrifice quality for any reason, this is our bottom line.

5. What's your lead Time?

Around 7-10 days for most filter elements

Around 15 days for water treatment equipments and small oil filter cart

Around 25-30 days for the Oil Coalescer purifier and Vacuum oil purifier

Zhengzhou Fluidguard Machinery Equipment Co., Ltd. TEL: 0086-0373-5128206

Zhengzhou Fluidguard is a collection of filter strainer, filter element, oil purifier and air compressor design and manufacturing, online sales and marketing as one of the modern manufacturers