Function: removing mechanical impurities

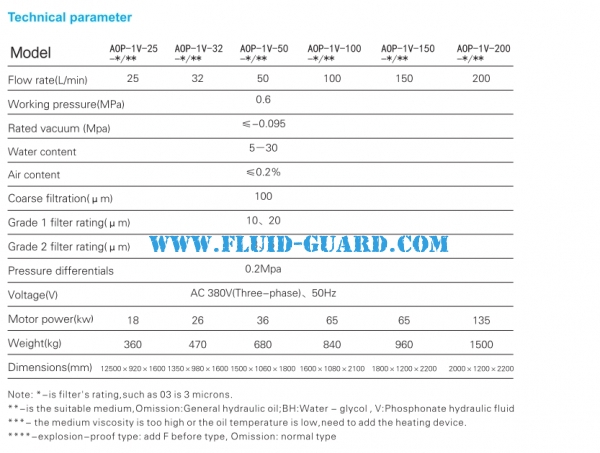

Motor power: 18-135 kw

Voltage: 380 V

Get QuotationProduct Details

Applications

Purification of turbine oil and transformer oil

Water removal and impurity filtration of oil in hydraulic lubrication system

Overall improvement of cleanliness of hydraulic lubrication system

Regeneration and purification of various oils

Technical principles

Different liquids have different saturated vapor pressures. At a temperature of 70°C, water starts to boil at a pressure of approximately 3×104Pa, while oil can only boil at a low pressure of 5Pa.At the same temperature, the saturated vapor pressure of oil is much lower than that of water.Therefore,when the pressure of the oil liquid surface is reduced to below the saturated vapor pressure of water by vacuuming, the water in the oil liquid will violently vaporize and overflow from the oil in the form of steam.

Through the suction of the vacuum, the oil enters the vacuum tank from the top and sprays down through the nozzle. The water in the oil vaporizes in the vacuum chamber and is pumped out by the vacuum pump,and the oil after water removal is discharged from the bottom.The middle of the vacuum chamber is filled with lipophilic material, so that the sprayed oil is dispersed on the surface of the filling material to form a thick oil film to increase the area of the gas-liquid interface and prolong the oil staying in the gas phase space.

The effect of vacuum water removal is mainly related to the working vacuum degree and oil temperature. The lower the vacuum degree and the higher the temperature,the better the water removal effect.The oil temperature is generally around 60° C. Excessive temperature will accelerate the oxidation of the oil.

For hydraulic oil, the vacuum degree is generally 60O-70OPa, which can reduce the water content in the oil to below 1000ppm. For transformer insulating oil, a higher degree of vacuum can be used, and the water content can be reduced to 10 ppm.

Vacuum dehydration can effectively remove all kinds of water in the oil, and can remove air and various volatile substances in the oil.

Clear the water

The free water and dissolved water in the oil deteriorate the oil by reducing lubricity, oxidation and acid formation. The non-aqueous oil is not easy to oxidize and form organic acids even if exposed to high temperature. The presence of organic acid compounds causes corrosion. Water accelerates the thermal degradation of oil to produce particles or carbonaceous substances.The presence of water also causes the oil to polymerize to form macro-molecules. Polymerization causes changes in viscosity, creating harmful solids that clog orifices and wear system components.

AOP-1V high-efficiency vacuum oil filter can remove 100% of free water and more than 95% of dissolved water.

Clear the Air

AOP-1V efficient vacuum oil purifier can remove 100% of free air and up to 75% of dissolved air, The air is removed as the oil passes through the vacuum tank. Other gases depending on the cycle time is reduced to trace amounts.

Clear the solid particles

In order to remove suspended particulate matter, ZLYC high-efficiency vacuum oil filter can filter out particles that cause abrasive wear in bearings, pumps and valves through three-stage filtration. It also removes sludge that may accumulate in the gap between the valve core and the valve sleeve and cause seizure and instability in the electro-hydraulic servo valve. In insulating oil, the secondary side filter level can prevent electrical breakdown caused by the bridging effect of charged particles.

Features

Vacuum System

It is composed of vacuum tank,vacuum pump,condensing tank,liquid accumulation tank,and air supplement system. The optimized structure design greatly increases the surface area of the oil in the vacuum system and maximizes the stroke of the oil in the vacuum system. Make the water and gas in the oil overflow sufficiently.This machine adopts an advanced anti-foaming system, so that the oil filter will never show the oil injection phenomenon that is common in similar products.

Filtration system

Three-stage filtration is adopted, and the coarse filter at the suction port protects the oil pump and prolongs the service life of the main filter. A two-stage fine filter is installed behind the pump to make the oil quickly reach a high degree of cleanliness.The filter material adopts special gradual aperture glass fiber material,which can filter particles of different sizes in layers,which greatly improves the service life of the filter element. With a complete filter element structure, it can effectively reduce the surface flow rate of the filter material and obtain stable filtration precision.

Heating system

It adopts step-by-step heating,the surface heat load is less than 1.0W/cm3 , and the oil will not deteriorate due to overheating. The oil temperature can be arbitrarily adjusted from 0 to 100° C,automatically controlled, and equipped with a protection device. When the oil intake is too small, it will automatically stop working to avoid damage to the heater caused by dry burning.

Automatic control system

This machine adopts a series of automatic control instruments such as frequency converter,liquid transmitter,liquid level transmitter,temperature sensor,vacuum sensor,etc.,to collect various information of equipment operation, and hand it to the central processor to process and automatic ally control the operation of the entire equipment and monitor the operating status of the equipment.This machine is equipped with various protection devices (overload protection,edge voltage protection,phase sequence protection, abnormal operation shutdown protection) to ensure the safe operation of the equipment.

Zhengzhou Fluidguard Machinery Equipment Co., Ltd. TEL: 0086-0373-5128206

Zhengzhou Fluidguard is a collection of filter strainer, filter element, oil purifier and air compressor design and manufacturing, online sales and marketing as one of the modern manufacturers